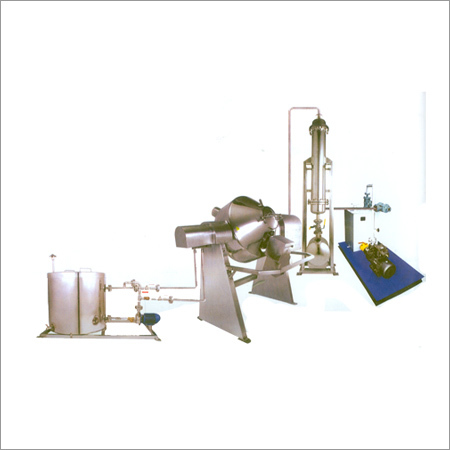

Double Cone Vacuum Dryer with Heating System And Vacuum Jet Ejector

Product Details:

- Type Double Cone Vacuum Dryer with Heating System & Vacum Jet Ejector

- Material Stainless Steel

- Computerized No

- Automatic Grade Automatic

- Voltage 220 Volt (v)

- Click to View more

Double Cone Vacuum Dryer with Heating System And Vacuum Jet Ejector Price And Quantity

- 1 Unit

- 1200000 INR/Unit

Double Cone Vacuum Dryer with Heating System And Vacuum Jet Ejector Product Specifications

- No

- Automatic

- Double Cone Vacuum Dryer with Heating System & Vacum Jet Ejector

- Stainless Steel

- 220 Volt (v)

Double Cone Vacuum Dryer with Heating System And Vacuum Jet Ejector Trade Information

- Cash in Advance (CID) Cheque Cash Advance (CA)

- 10 Unit Per Week

- 1 Week

- All India

Product Description

Double Cone Vacuum Dryer with Heating System & Vacum Jet Ejector

Applications

RCVD is suitable for drying & mixing powder (raw materials), pharmaceutical materials, crystalline products, insecticides, pesticides, food products & also for heat sensitive products. The equipment can also be used as rotary evaporator.

Working Principle

Raw material is charged in batches & is subjected to indirect heating while at the same time undergoing rotary motion of the cone assembly. The conical shape of the dryer ensures efficient circulation of hot liquid heating media.

Drying takes place when heat flows from outer cone through a jacket, and vacuum is applied in the inner cone. The drying operation is based on the principle that water or other volatile product moves from a zone of low pressure. This is accomplished by warming the product to be dried to raise the vapour pressure of the zone of low pressure. This is accomplished by warming the product to be dried to raise the vapour pressure of the absorbed or free liquid, by vacuum, or by sweeping it away with an air current. Thus the essential conditions for effective drying are efficient and uniform heat transfer throughout the batch and rapid removal of the vapour.

PROMASTM Rotary Double Cone Vacuum Dryer is unique in removing complete water, or other solvent from wet powders coming from a filtration unit or a centrifuge. It can be used as an effective dryer, fast mixer & blender or homogenizer. It can also be used as a granulator.

The drying time is substantially reduced because of high-speed choppers, which help the evaporation of the solvent or moistures. Chopper speed can be controlled by a frequency drive. Dryer are manufactured as per "US-FDA" Standards & Regulations.

Salient Features

- Low temperature drying under vacuum.

- Highly efficient for uniform drying in a short time as co-efficient of thermal transmission is high.

- Solvent recovery can be carried out.

- Specially designed micro air-filter can be provided on receiver while breaking vacuum for safety operation.

- The discharge of the dried material is easy due to the conical configuration of the dryer & it is possible to fix vibrator.

- Nitrogen purging system is available optionally for mechanical seal as well as for cleaning filter.

- Specially designed S.S. Rotary union is provided for hot water or steam at inlet & outlet. Mode of heating is indirect through steam I hot water or hot oil.

- A self-cleaning butterfly discharge valve with safety blind cover.

- Internal cartridge filter for fine powders with effective surface area.

- Available in STD/GMP/cGMP/GAMPI

- GLPI GCP/Lab Models and kilo lab models.

- Capacity available: 5 Ltr. To 5000 Ltr.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese