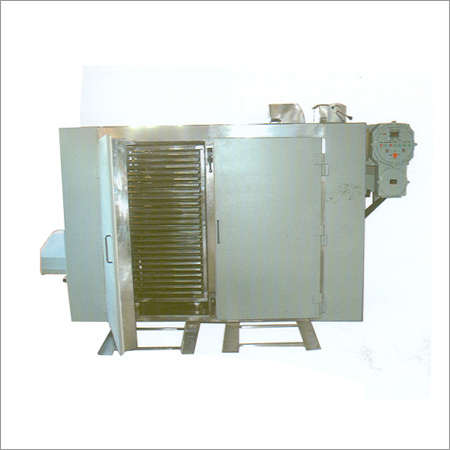

Industrial Air Tray Dryers

Product Details:

- Drive Automatic

- Heating Power Electric Kilowatt (kW)

- Power Consumption 5 to 25 Kilowatt (kW)

- Place of Origin Indian

- Power Source Electric

- Click to View more

Industrial Air Tray Dryers Price And Quantity

- 1200000 INR

- 1 Unit

Industrial Air Tray Dryers Product Specifications

- Electric Kilowatt (kW)

- Automatic

- Electric

- 5 to 25 Kilowatt (kW)

- Indian

Industrial Air Tray Dryers Trade Information

- Cash in Advance (CID) Cheque Cash Advance (CA)

- 10 Unit Per Week

- 1 Week

- All India

Product Description

Air Tray Dryers (ATD)

Application

Most of the users are from Pharmaceutical, Chemical, Dyestuff, Textile, Food, Automobiles & many other industries.

The tray dryers are heated by means of electrical, steam or oil/ gas fired burners. Promas TM dryers are specially designed to have better efficiency than any other dryers available from other tray dryer manufacturers.

Construction

The dryer cabinet is designed in such a way that the airflow inside the dryer has minimum resistance. Internal surfaces of the dryer are made with well-rounded corners with maximum angle so as to offer least resistance to airflow, resulting in less pressure drop across the corners. The outer body is also fabricated with rounded edges without steps from outside to have smooth finish. The inside fan & radiator / heaters are covered with SS / GI mesh to have safety in operation. The drying oven model having MS body from outside & SS body inside is provided with 150 mm SS collar around the door.

Sealing

The shafts of circulation fan, the inlets & outlets of the radiator coil are sealed by food grade sealing pads which stops the leakage of hot air from the drying cabinet.

Leakages increase drying time of the product inside the trays of the dryer & in some cases causel the air contamination of air inside the dryer. Thus sealing helps to save the energy of drying process.

The inlet (suction) of the dryer is provided with 10 micron filter to avoid air contamination. The exhaust of the dryer is provided with either manual or motorized operated damper and can be operated precisely for various positions of the damperfrom the main control panel board.

The outer body is also polished to 180-220 grit finish with step-less body for GMP model tray dryers.

We offer both economy models and GMP models

Economy models of Tray Dryer the inside SS sheets are of 18-swg, AISI 304/316, tag welded & mirror finished, while for the GMP models the inside of the dryers are made of either 14-16 swg thick sheet fully welded from inside and polished to mirrorfinish.

Material of Construction

The dryer are manufactured in various combinations according to the requirement & the products to be dried. For example,

- AISI304 inside orAISI316 on the outside.

- AISI316 on both inside and outside.

- AISI304 orAISI316 inside and M.S outside

- Sheet thickness as per customers' Specifications

The doors of the dyers are provided with groove & with hollow "0" shaped food grade Silicon / Neoprene gasket to have leakage proof door. The locks are either ball catch or bolt type lock arrangement.

All the dryers are provided with necessary control panel boards. The dyers are supplied with either FLP or NON-FLP controls & drives.

Air Circulation

Air in the dryer is circulated by means of fan fitted on the side of the dryer. The fans are made out of AISI 304/316 or MS with SS / MS / EN8 shafts driven by suitable motors. The shafts are well balanced dynamically & are provided with balancing test certificates.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese